technology

stained glass

This technique involves mouth-blown glass, cut into shapes, perhaps painted and fired, and then held together in a mosaic of lead. The industry is permanently renewed by the need to restore and upkeep so much medieval and victorian stained glass. As a medium for modern glass art it is still relevant in older buildings but less used in contemporary buildings.

laminated antique glass

This technique involves genuine mouth-blown glass, which has a rich colour, texture and beauty unmatched by more contemporary methods, bonded to large sheets of float glass. The antique glass has to be cut accurately to create a tight mosiac. The technique enables the overall panels to be large, and creates a more fluid aesthetic without the required black outlines of lead.

transparent enamels

These can be screen-printed, airbrushed or painted onto glass and then fired. The glass can be transparent or etched. The colours can be very rich and deep, though some specific colours cannot be achieved with these enamels. There is something mysterious and alchemical about transparent enamels – they can be unpredictable when mixed and even show subtle changes in colour depending on whether you print on the tin side of glass or not! Printing can be done one colour at a time, on one surface of a piece of glass only. The enamelled glass is fired in the toughening plant, thus the emerging product can be of any thickness and can conform to all building regulations.

opaque enamels (fritted glass)

These are much more widely used commercially, the result frequently being referred to as ‘fritted glass’. The opaque enamels are more predictable than transparent enamels, and can achieve almost any colour. They show up equally from the interior or the exterior. But, they are not same as transparent colours and, in my view, can seldom match them in subtlety and beauty.

digital opaque enamels

These are essentially the same medium but, instead of being screen-printed onto the glass one colour at a time, they pass through an ink-jet system. Thus a multicolour image can be created in a single process. After printing the enamels are fired in the normal way making them completely permanent. The process, as so often with the latest technology, is produced at much lower cost.

digitally printed interlayers

This process is a digitally printed film laminated between two panels of glass. The laminate material on either side of the glass provides a substantial, but not 100%, protection against degradation of the printed colours from daylight.

resin painted glass

This is a technique not widely used, but that has applications in certain contexts. Optimally the shapes are carved into glass with a sandblaster. This creates a perfect bonding surface for the resin as well as defined shapes for the colours. The colour is then poured or painted onto the surface of the glass. This resin brings the glass back to transparent, which makes the colours very striking. The colours can be very rich and can be mixed to create striking effects.

slumped glass

Glass is heated over a mould to a temperature that allows the glass to slowly sag into a mould. Moulds can be created from many different materials giving many different effects. The availability of computer controlled kilns, that can heat and cool glass at controlled speeds, transformed this process from something complex and time consuming to something that can almost be done at the push of a button. The range of shapes, textures is infinite. The glass can be toughened. The technique creates a glass that is very textural and organic and works very well in older buildings as well as new.

fused glass

This is a process where layers of glass are heated to quite high temperatures so that they fuse together. This can be done with coloured glass, powdered colours, layers of float glass, creating different shapes etc.

etched glass

Etching glass refers to both acid-etching and sand-blasting, both of which remove the transparency from glass by changing the surface. Acid etching is less used now as there are ceramic enamels which almost perfectly mimic the effect of acid etching. This means that repeated patterns can be created at very low cost, and a the effect is much more durable and scratch resistant than acid etching. Sandblasting is mainly a way of carving into glass and thus creating relief patterns.

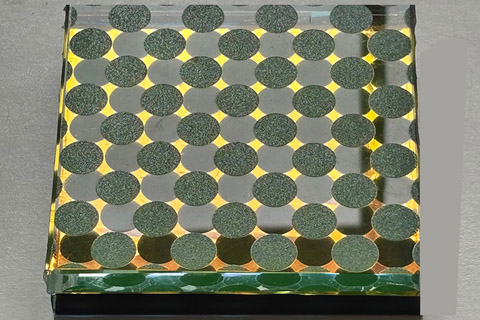

dichroic glass

This is just one of many different types of glass on the market. Dichroic glass has a coating which means it is sometimes transparent and sometimes reflective and each mode reveals a different colour. Mostly the glass will be somewhere between these two extremes so the glass can reveal many different mixtures of colours. - or for short film here.